Introduction

Interlog is a concept for a way to manufacture plywood furniture without using glue to keep the plies together. Unlike plywood, it can be shipped in a very flat package, assembled at home, and is completely biodegradable.

It has been nominated for the Green Concept Award 2023.

About

The flat sheets and the assemble-at-home concept make for the possibility of using very flat and space-efficient packaging. This drastically reduces the volume needed for transportation compared to a pre-assembled version of the same product. This efficiency will dramatically increase the number of products shipped per container, truck, etc., reducing the delivery's footprint.

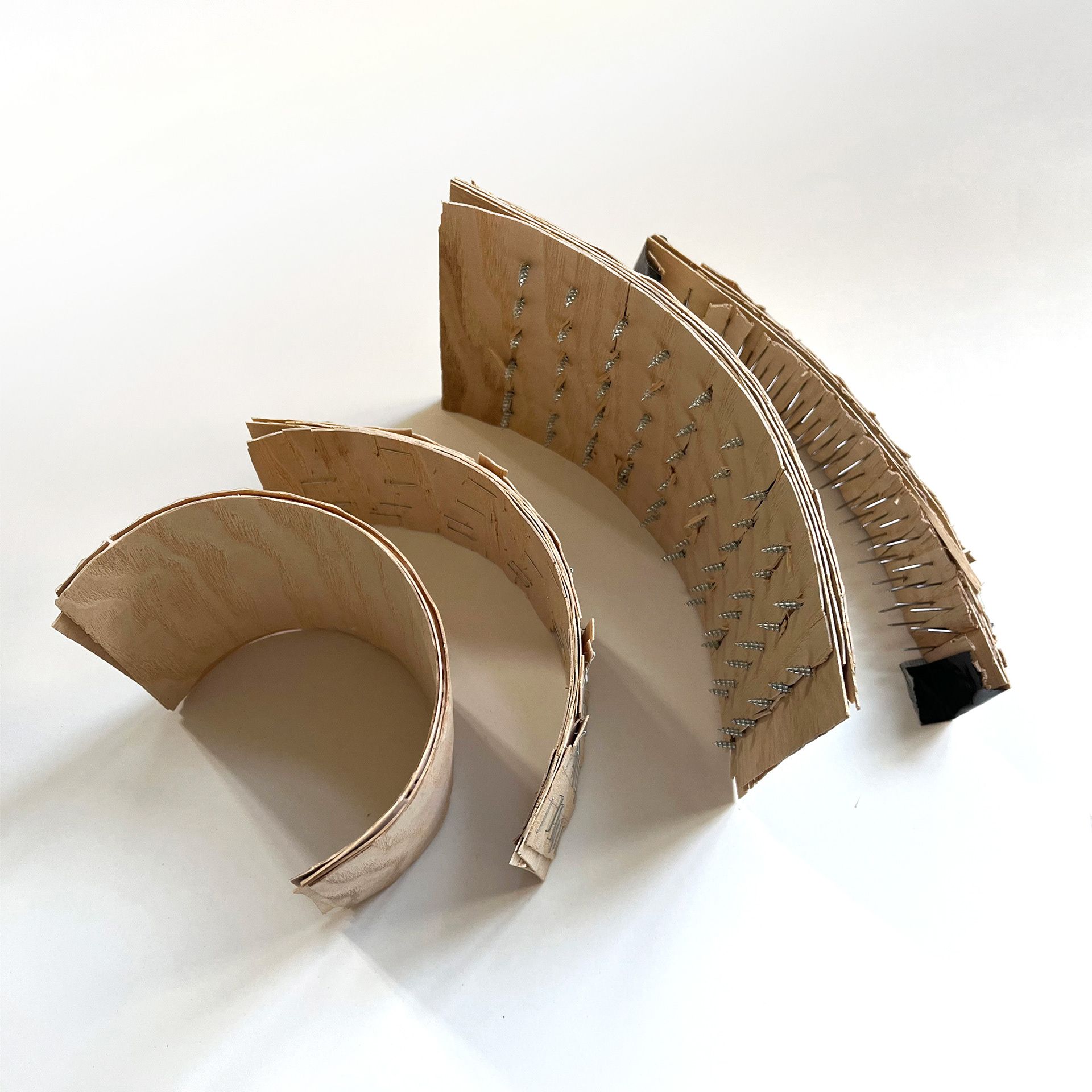

Because of the easy assembly and disassembly, it’s also possible to create objects that consist of two different materials - even organic and synthetic - that are still easily separable.

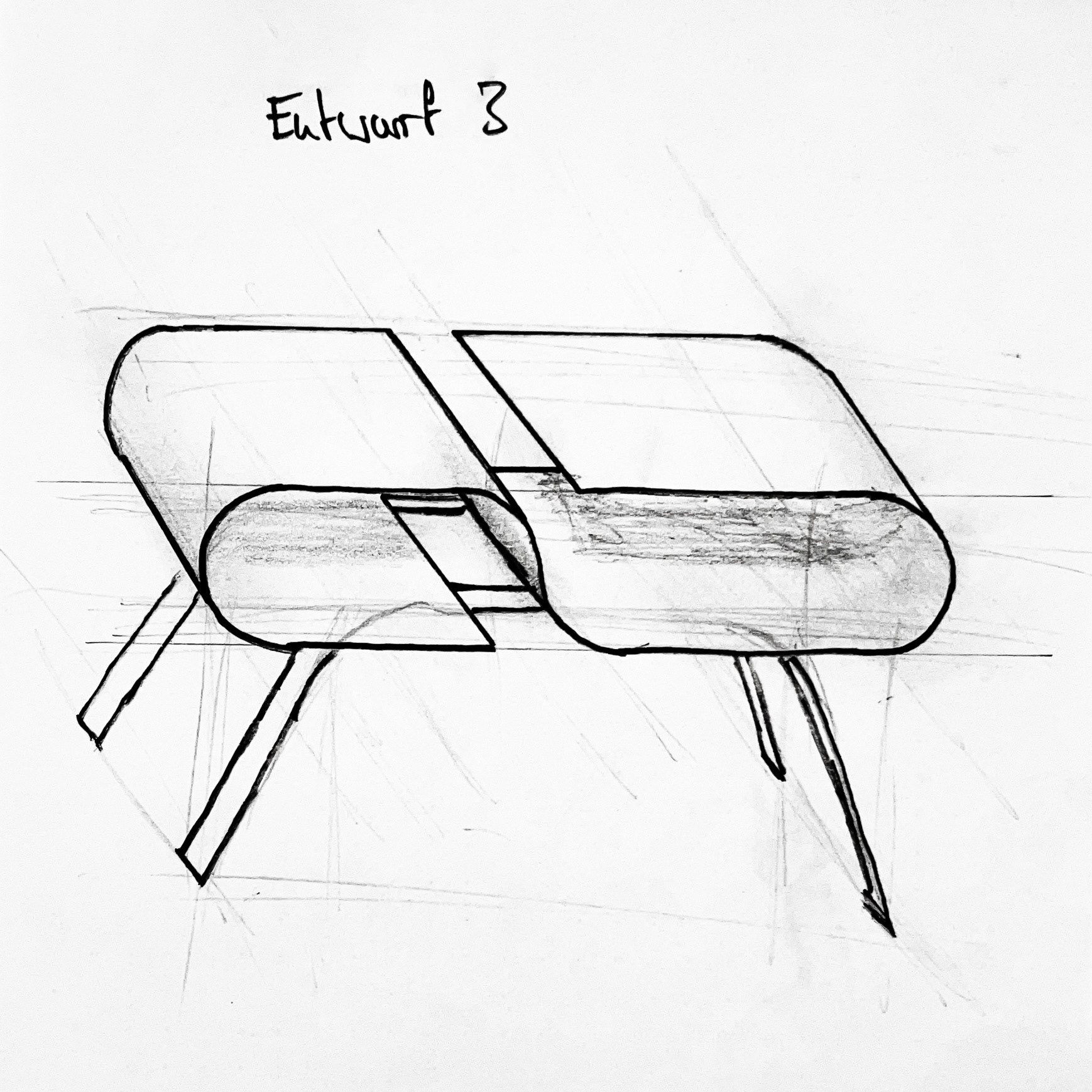

Even though the product you can see is more a proof of concept rather than a finished design, this nightstand is aesthetically pleasing and features two shelves in a single body. The colour and shape of the metal provide a nice contrast to the organic look and feel of the wood.

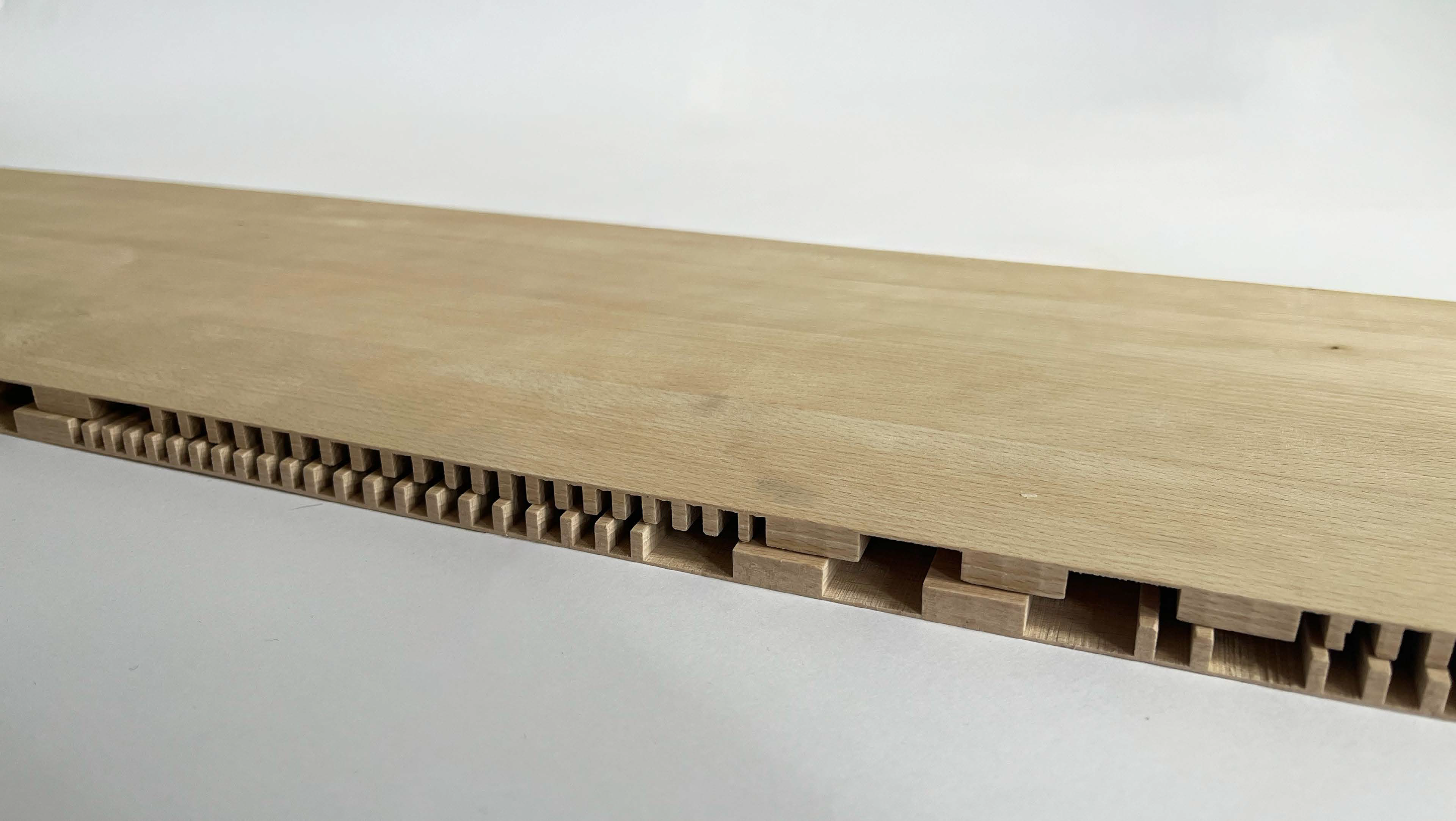

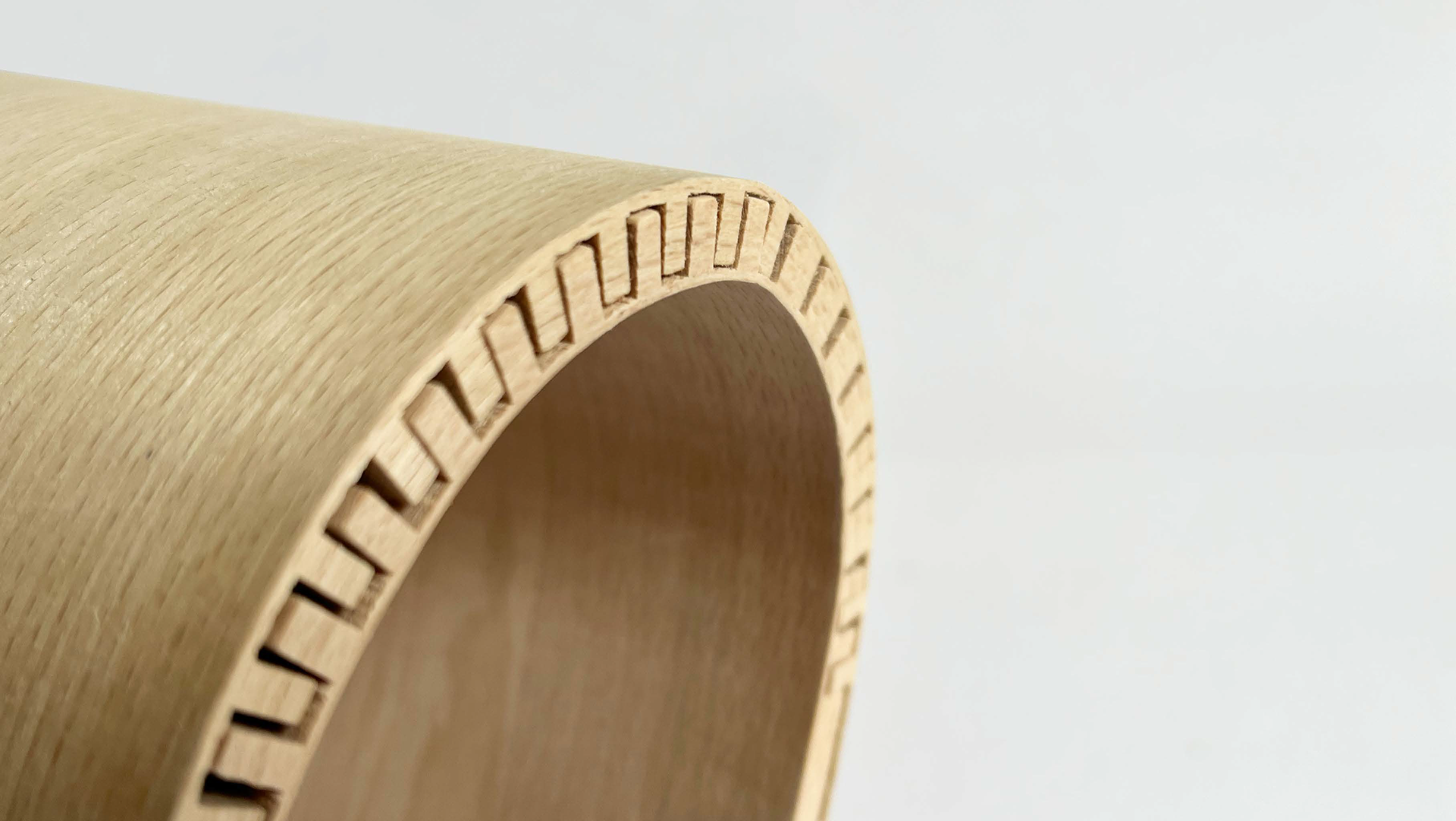

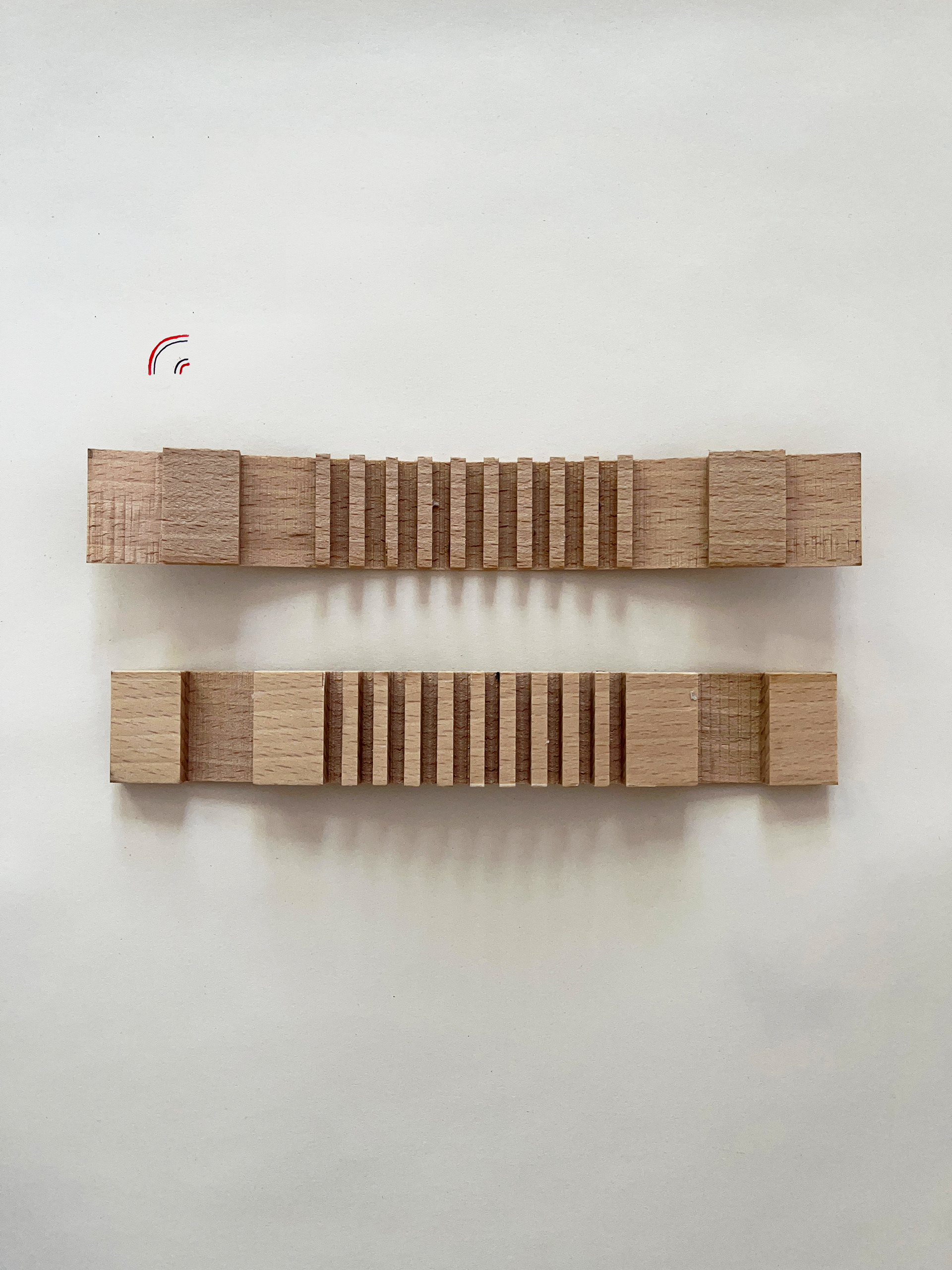

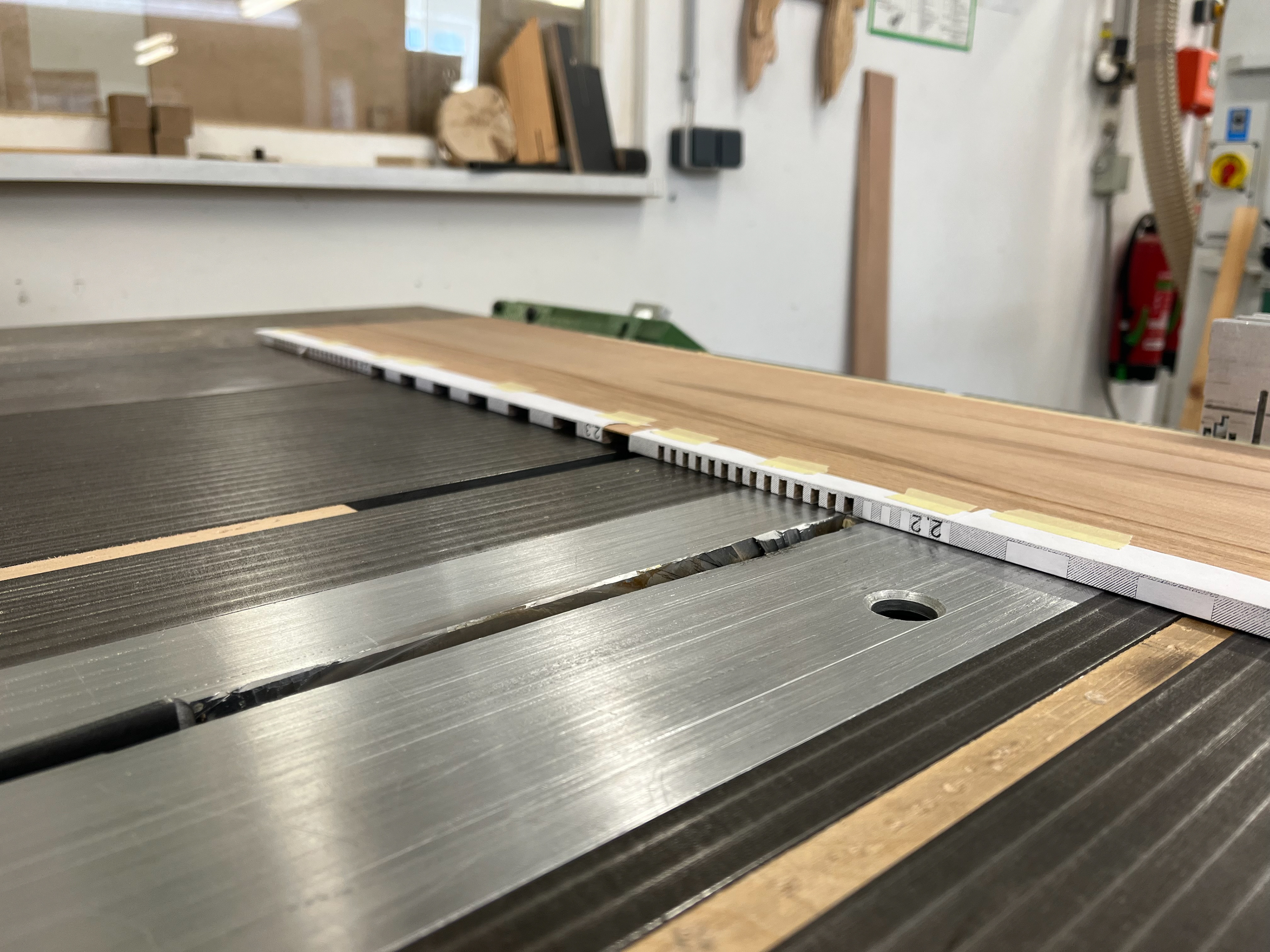

Another striking detail is each of the two smooth curves that feel very nice to the touch and are definitely an eye-catcher. The innovation lies in the way the two wooden sheets come together. They are machined to click perfectly into each other and through the different spacing of the teeth, they assume a predetermined shape. If fabricated with the required accuracy, this creates very stable curves and also straight parts that can take a considerable load.

All of this makes for a piece of furniture that can be bent and clicked into shape at home and doesn’t need any screws or glue to keep its shape.

This project was done in a course at Hochschule Anhalt, Dessau.

Process

From the beginning on, a big focus is to not mix organic with synthetic materials, for example by using glue, but still achieving similar properties as plywood.

Regular plywood uses glue that is predominantly synthetic and not biodegradable. Therefore the wood is not contaminated and can be returned to the organic cycle at the end of the product’s life span.

I experimented with different ideas that I've had for achieving this.

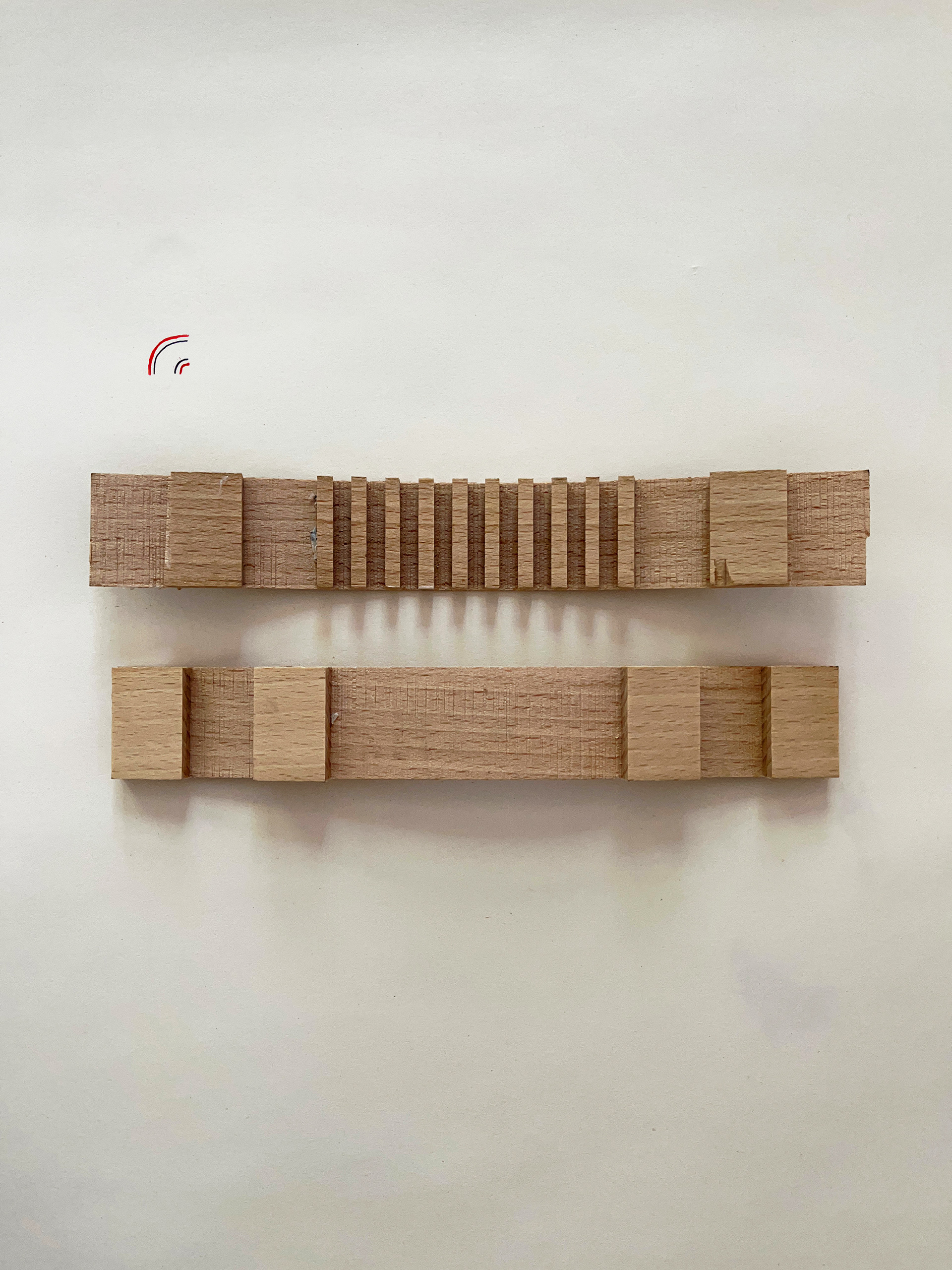

First Prototype

After sketching some designs and trying them in CAD, I made the first prototype.

Unfortunately, it didn't go according to plan.

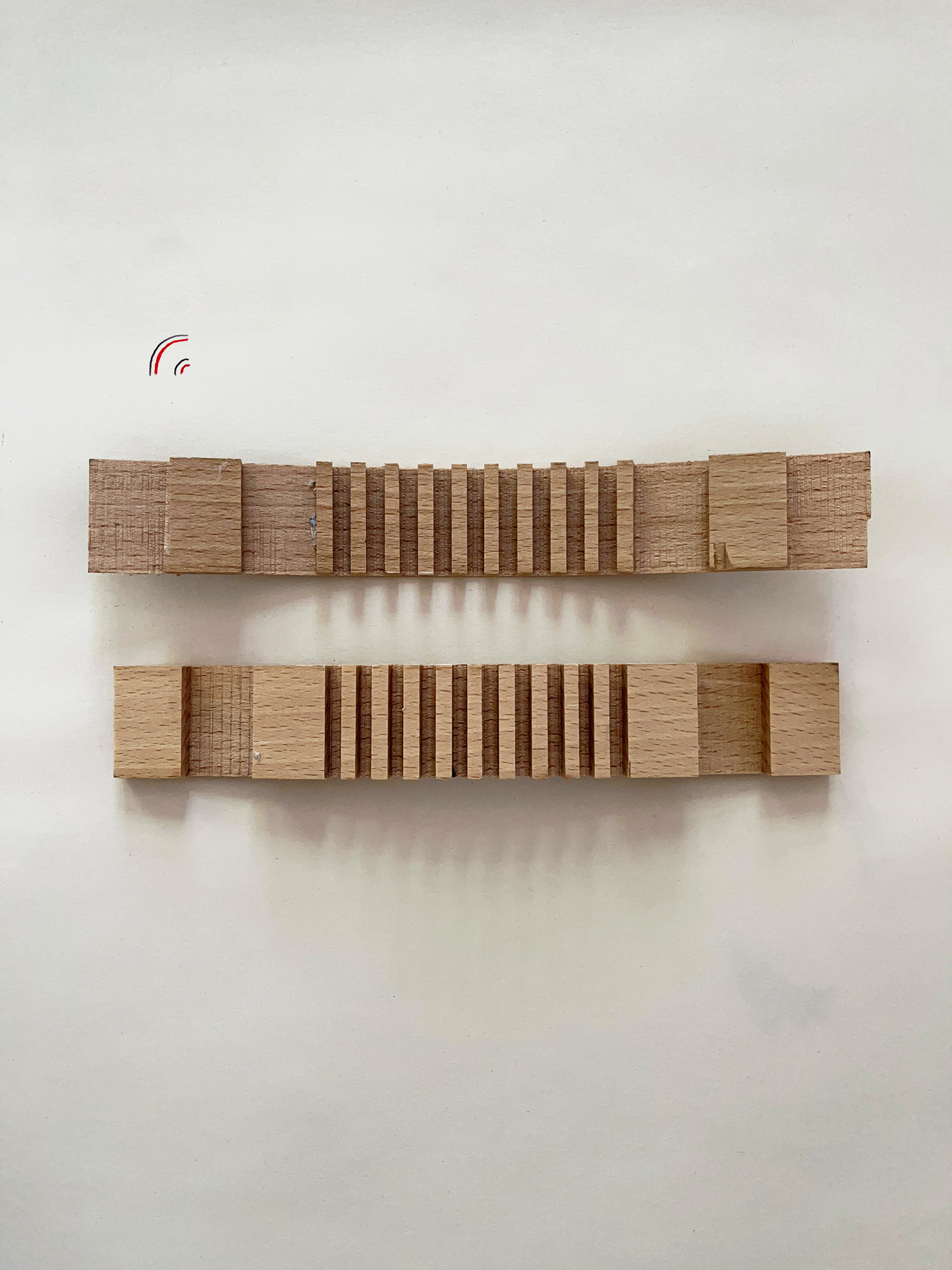

Second Prototype

With all the learnings from the first attempt, I made a second prototype with a simpler shape and I am very happy with the result.

July 2022